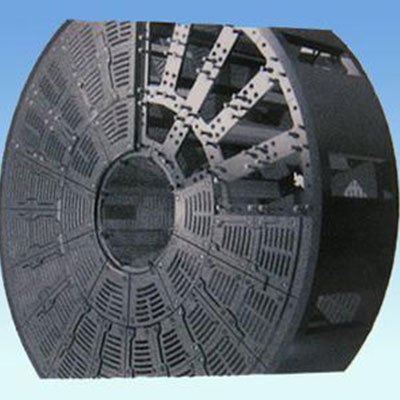

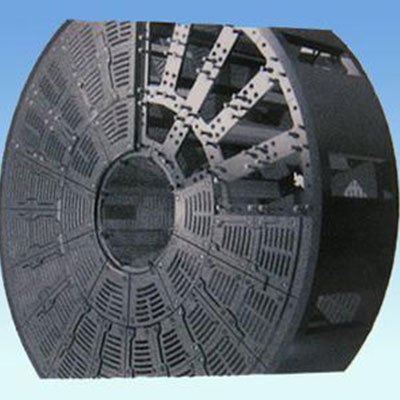

Diaphragm of Cement Mill

cement mill diaphragm

Intermediate diaphragm of the Cement Mills

Alloyed high manganese steel Diaphragm

The barrel is divided into intermediate baffles of two or three grinding bins. Theseparating wearhouse plate has holes that are smaller than the diameter of the steel balls in the two abrasive cavities to allow the material to pass through and be further milled. Due to long-time friction between steel balls and materials in the two sides of the abrasive silo, the silo panel needs to be very wear-resistant to shorten the replacement cycle. Some ball mills use double-layered diaphragms to better distinguish the two abrasive cavities and prevent them from collapsing and damaging the body.

The double storey partition board is also a kind of separating wearhouse plate, and the materials used are basically the same.

If you don't find the product you need on the website, please email us(info@lyzhili.com), because we are a customized factory for crusher spare parts.

Feature:

We use proper alloying and and related technological measures to make the blow bars’ surface hardness reaches more than 58HRC , during the process of wearing will maintain high hardness and high wear resistance.

Technology process

In blow bars’ working part we use the technique of directional solidification to make Cr7C3 type carbide is perpendicular to the part.The macro-hardness and micro hardness of carbide can be improved without reducing thoghness.

Application

Suitable for making wearable spare parts with lower impact load and simpler shape.

Chemical component

Grade | Chemical component% | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | Ni | Cu | S | P | |

| BTMCr15 | 2.0~3.3 | ≤1.2 | ≤2.0 | 14~18 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| BTMCr20 | 2.0~3.3 | ≤1.2 | ≤2.0 | 18~23 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| BTMCr26 | 2.0~3.3 | ≤1.2 | ≤2.0 | 23~30 | ≤3.0 | ≤2.5 | ≤2.0 | ≤0.06 | ≤0.10 |

| 1:Allowed to add microscale V,Ti,Nb,B and Re etc. 2:We will choose grade and specific component according to blow bars’ weight ,thickness and sizes | |||||||||

Mechanical Property

Grade | Surface Hardness | |||||

|---|---|---|---|---|---|---|

Casting condition | Harded condition | Softening annealing condition | ||||

| HRC | HB | HRC | HB | HRC | HB | |

| BTMCr15 | ≥46 | ≥450 | ≥58 | ≥650 | ≥41 | 400 |

| BTMCr20 | ≥46 | ≥450 | ≥58 | ≥650 | ≥41 | 400 |

| BTMCr26 | ≥46 | ≥450 | ≥58 | ≥650 | ≥41 | 400 |

1:There are no exact corresponing value between rockwell hardness(HRC) and brine hardness(HB),so ,this two kind of hardness value can be inspend used 。

| ||||||

Feature

High manganese steel refers to high alloy steels containing more than 10% manganese. The biggest features of high-manganese steel are:

The greater external compressive stress or impact load, the more conducive to the formation of hardened layer, so the higher the wear resistance of the casting;

With the gradual wear of the hardened layer, new work hardened layers will continue to form under the influence of external compressive stress or impact loads. Therefore, it is suitable for making wearable spare parts that are subject to high impact load and wear for a long time, and is widely used in metallurgy, mining, building materials, railways, electric power, coal and other broken grinding equipment.

Chemical component

| Grade | Chemical component % | |||||

|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | S | P | |

| ZG120Mn13 | 1.05~1.35 | 0.3~0.9 | 11~14 | - | ≤0.06 | ≤0.04 |

| ZG120Mn13Cr2 | 1.05~1.35 | 0.3~0.9 | 11~14 | 1.5~2.5 | ≤0.06 | ≤0.04 |

| ZG120Mn17Cr2 | 1.05~1.35 | 0.3~0.9 | 16~19 | 1.5~2.5 | ≤0.06 | ≤0.04 |

| 1:Allowed to add microscale V,Ti,B and Re etc. 2:We can produce the other grade high manganese steel hammer according to customers’ requirments | ||||||

Mechanical Property

Grade | Stretch property | Hardness HB | |||

|---|---|---|---|---|---|

| yield strength ReH/Mpa | tensile strength Rm/Mpa | Section elongation% | impact absorbing energyKu2J | ||

| ZG120Mn13 | - | ≥685 | ≥25 | ≥118 | ≤300 |

| ZG120Mn13Cr2 | ≥390 | ≥735 | ≥20 | - | ≤300 |

Feature

The alloy structure cast steel is an iron-carbon alloy formed by adding an appropriate amount of one or more alloy elements on the basis of ordinary carbon steel.

Process technology

According to the different elements added, with appropriate smelting and heat treatment process to obtain high strength, high toughness, high wear resistance, corrosion resistance, low temperature resistance, high temperature resistance, non-magnetic and other related special properties.

Scope of application

It is suitable for producing the wear-resisting spare parts with good mechanical strength and good toughness that are required for various working conditions, and the main steel structure castings with the required dynamic load.

Chemical component

Grade | Chemical component% | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | S | P | Ai | |||

| ZG42CrMo | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | 0.80-1.10 | 0.15-0.25 | <0.04 | <0.035 | - | ||

| ZG35CrMo | 0.32~0.40 | 0.17~0.37 | 0.40~0.70 | 0.80~1.10 | 0.15~0.25 | ≤0.035 | ≤0.035 | - | ||

| ZG38CrMoAl | 0.35~0.42 | 0.20~0.45 | 0.30~0.60 | 1.35~1.65 | 0.15~0.25 | ≤0.04 | ≤0.04 | 0.7~1.1 | ||

| ZG40Cr | 0.37~0.45 | 0.17~0.37 | 0.5~0.8 | 0.8~1.1 | - | - | - | - | ||

| ZG30Mn2SiCrMo | 0.25~0.35 | 0.40~0.80 | 1.20~1.60 | 1.35~1.65 | 0.2~0.5 | ≤0.04 | ≤0.04 | - | ||

Mechanical Property

| Grade | tensile strength(Mpa) | yield strength (Mpa) | Elongation at cross section(%) | Section shrinkage rate(%) | Shock absorption energy(KV2/J) |

|---|---|---|---|---|---|

| ZG42CrMo | ≥1080 | ≥930 | ≥12 | ≥20 | ≥24 |

| ZG35CrMo | ≥985 | ≥835 | ≥12 | ≥20 | ≥24 |

| ZG38CrMoAl | ≥980 | ≥835 | ≥14 | ≥20 | ≥24 |

| ZG40Cr | ≥980 | ≥785 | ≥9 | ≥20 | ≥24 |

| ZG30Mn2SiCrMo | ≥1500 | ≥1300 | ≥3 | - | ≥24 |

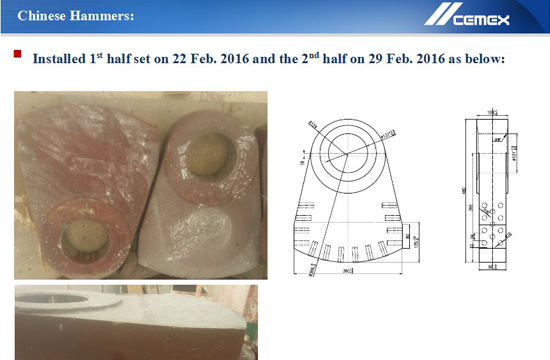

Analysis of the situation of CEMEX using our company's hammers

Learn More

Cement plant limestone crusher hammer use case

Learn More

Warmly celebrate the 10th anniversary of the cooperation between Luoyang Zhili a

Learn MoreThe products we have produced

Diaphragm of Cement Mill

cement mill diaphragm

Intermediate diaphragm of the Cement Mills

Alloyed high manganese steel Diaphragm

Sweep

Add friends

Wechat ID

+86-13353997333