Flat plate type medium carbon steel grinding table

Flat plate type medium carbon steel grinding table

Flat plate type medium carbon steel grinding table

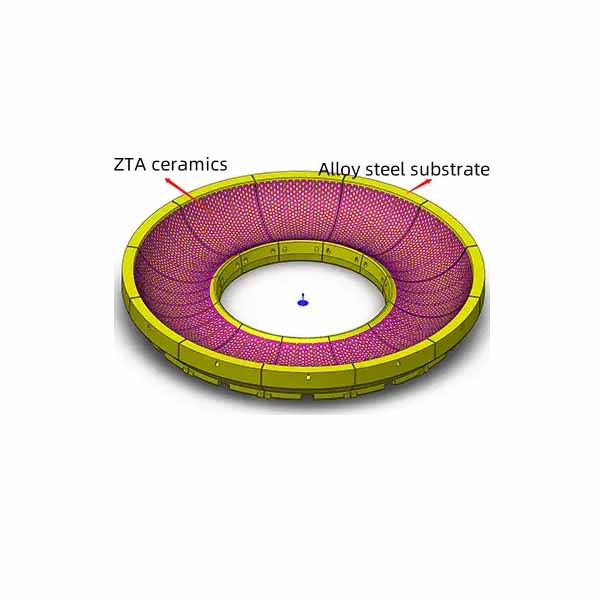

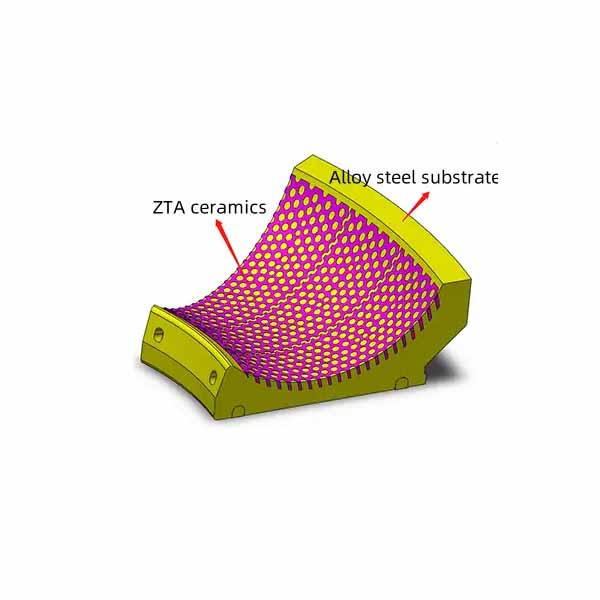

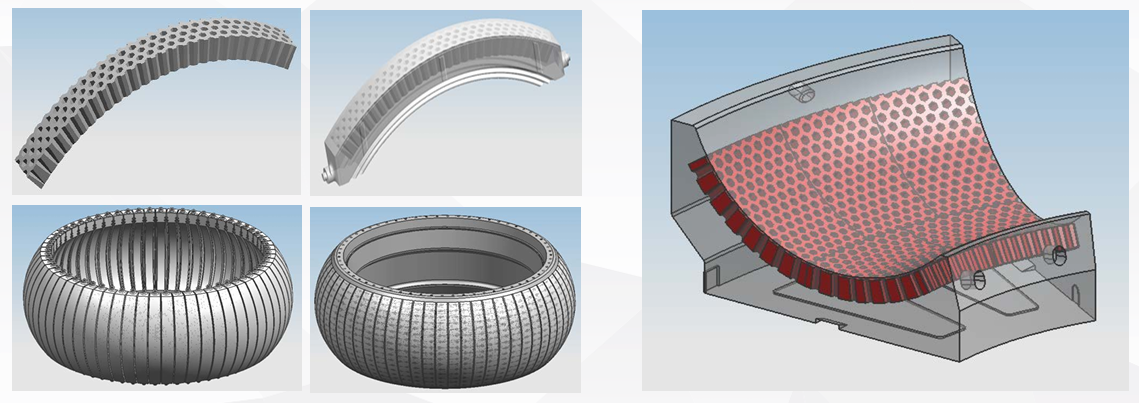

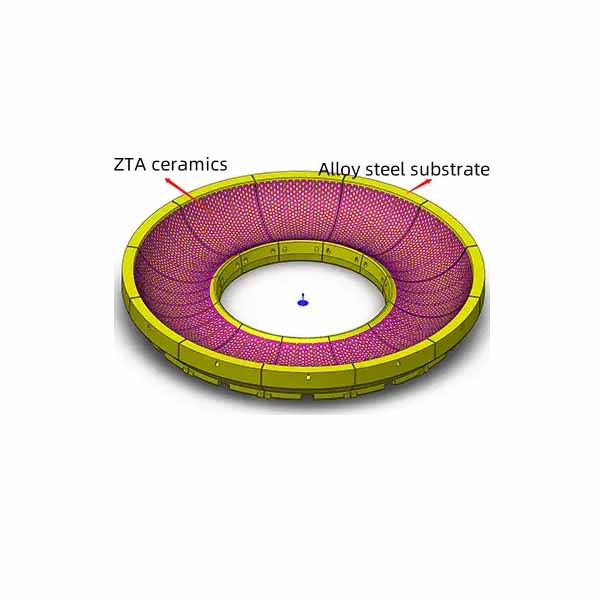

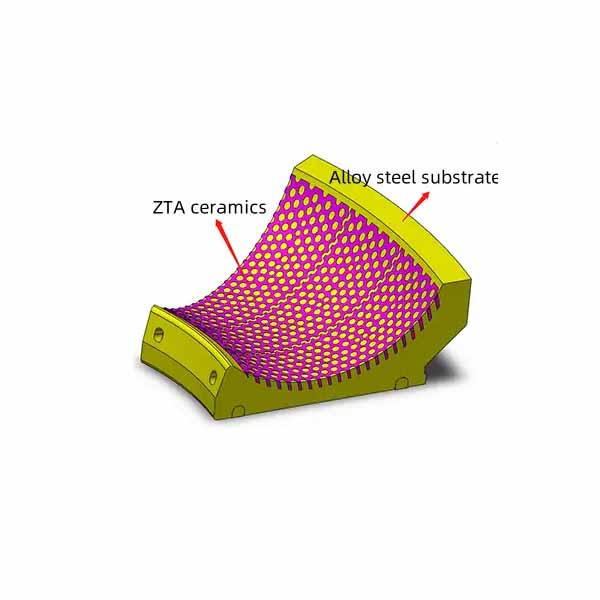

Ceramic Metal Composite Mill Liner

Ceramic Metal Composite Liner

The grinding table is mainly composed of disc body, lining plate, pressure block, material baffle ring, scraper plate, wind ring, air guide plate and other parts.

The vertical mill liner is divided into concave, flat plate and bowl type, which correspond to the tire type, taper and cylinder type of the grinding roller respectively. Commonly found in the market are concave and flat table.

The table is rotated by the speed reducer, and the material falling on the center of the disc is dispersed by the centrifugal force to the gap between the grinding roller and the disc and subjected to the squeezing friction to achieve the purpose of grinding the powdery material.

At present, in order to extend the life cycle and reduce costs, welding rods made of wear-resistant materials are often used for surfacing on the surface of the grinding table. Achieve the effect of multiple use of a single table. Surfacing layer can adapt to a variety of working conditions, avoiding the need to replace the entire table due to changes in working conditions.

If you don't find the product you need on the website, please email us(info@lyzhili.com), because we are a customized factory for wear spare parts.

Feature:

1. Possessing the characteristics of ceramics and metals

Ceramic alloy composite products combine the characteristics of ceramics and alloys. They have both the wear resistance of ceramics and the mechanical properties of alloys, and are not easy to break or fall off.

2. Surface honeycomb structure

Due to the different properties of ceramics and alloys, the height difference of the surface is caused, thus forming a honeycomb structure. This structure increases the friction force and effective contact area of the surface, which helps to improve the grinding or crushing efficiency.

3. Extend the service life of equipment

The hardness of the wear-resistant part matrix is ≥60HRC, and the wear resistance is good.

The working surface is reinforced with ceramic particles with a hardness of 1900-2100HV, which makes the surface have excellent wear resistance, thereby greatly improving the service life of the equipment. Under normal conditions, it can reach 2~3 times that of ordinary materials.

Feature:

We use proper alloying and and related technological measures to make the blow bars’ surface hardness reaches more than 58HRC , during the process of wearing will maintain high hardness and high wear resistance.

Technology process

In blow bars’ working part we use the technique of directional solidification to make Cr7C3 type carbide is perpendicular to the part.The macro-hardness and micro hardness of carbide can be improved without reducing thoghness.

Application

Suitable for making wearable spare parts with lower impact load and simpler shape.

Chemical component

|

Grade |

Chemical component% | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | Ni | Cu | S | P | |

| BTMCr15 | 2.0~3.3 | ≤1.2 | ≤2.0 | 14~18 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| BTMCr20 | 2.0~3.3 | ≤1.2 | ≤2.0 | 18~23 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| BTMCr26 | 2.0~3.3 | ≤1.2 | ≤2.0 | 23~30 | ≤3.0 | ≤2.5 | ≤2.0 | ≤0.06 | ≤0.10 |

|

1:Allowed to add microscale V,Ti,Nb,B and Re etc. 2:We will choose grade and specific component according to blow bars’ weight ,thickness and sizes |

|||||||||

Mechanical Property

| Grade | Surface Hardness | |||||

|---|---|---|---|---|---|---|

|

Casting condition |

Harded condition |

Softening annealing condition |

||||

| HRC | HB | HRC | HB | HRC | HB | |

| BTMCr15 | ≥46 | ≥450 | ≥58 | ≥650 | ≥41 | 400 |

| BTMCr20 | ≥46 | ≥450 | ≥58 | ≥650 | ≥41 | 400 |

| BTMCr26 | ≥46 | ≥450 | ≥58 | ≥650 | ≥41 | 400 |

|

1:There are no exact corresponing value between rockwell hardness(HRC) and brine hardness(HB),so ,this two kind of hardness value can be inspend used 。 2:The hardness in the 40%deepness of casting section should be lower than 92% hardness of surface. |

||||||

Feature

High manganese steel refers to high alloy steels containing more than 10% manganese. The biggest features of high-manganese steel are:

The greater external compressive stress or impact load, the more conducive to the formation of hardened layer, so the higher the wear resistance of the casting;

With the gradual wear of the hardened layer, new work hardened layers will continue to form under the influence of external compressive stress or impact loads. Therefore, it is suitable for making wearable spare parts that are subject to high impact load and wear for a long time, and is widely used in metallurgy, mining, building materials, railways, electric power, coal and other broken grinding equipment.

Chemical component

|

Grade |

Chemical component% | |||||

|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | S | P | |

| ZG120Mn13 | 1.05~1.35 | 0.3~0.9 | 11~14 | - | ≤0.06 | ≤0.04 |

| ZG120Mn13Cr2 | 1.05~1.35 | 0.3~0.9 | 11~14 | 1.5~2.5 | ≤0.06 | ≤0.04 |

| ZG120Mn17Cr2 | 1.05~1.35 | 0.3~0.9 | 16~19 | 1.5~2.5 | ≤0.06 | ≤0.04 |

|

1:Allowed to add microscale V,Ti,Nb,B and Re etc. 2:We will choose grade and specific component according to blow bars’ weight ,thickness and sizes |

||||||

Mechanical Property

|

Grade |

Stretch property |

Hardness HB |

|||

|---|---|---|---|---|---|

| yield strength ReH/Mpa | tensile strength Rm/Mpa | Elongation at cross section% | Shock absorption energyKu2J | ||

| ZG120Mn13 | - | ≥685 | ≥25 | ≥118 | ≤300 |

| ZG120Mn13Cr2 | ≥390 | ≥735 | ≥20 | - | ≤300 |

Feature

The alloy structure cast steel is an iron-carbon alloy formed by adding an appropriate amount of one or more alloy elements on the basis of ordinary carbon steel.

Process technology

According to the different elements added, with appropriate smelting and heat treatment process to obtain high strength, high toughness, high wear resistance, corrosion resistance, low temperature resistance, high temperature resistance, non-magnetic and other related special properties.

Scope of application

It is suitable for producing the wear-resisting spare parts with good mechanical strength and good toughness that are required for various working conditions, and the main steel structure castings with the required dynamic load.

Chemical component

|

Grade |

Chemical component% | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | S | P | Ai | |||

| ZG42CrMo | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | 0.80-1.10 | 0.15-0.25 | < 0.04 | < 0.035 | - | ||

| ZG35CrMo | 0.32~0.40 | 0.17~0.37 | 0.40~0.70 | 0.80~1.10 | 0.15~0.25 | ≤0.035 | ≤0.035 | - | ||

| ZG38CrMoAl | 0.35~0.42 | 0.20~0.45 | 0.30~0.60 | 1.35~1.65 | 0.15~0.25 | ≤0.04 | ≤0.04 | 0.7~1.1 | ||

| ZG40Cr | 0.37~0.45 | 0.17~0.37 | 0.5~0.8 | 0.8~1.1 | - | - | - | - | ||

| ZG30Mn2SiCrMo | 0.25~0.35 | 0.40~0.80 | 1.20~1.60 | 1.35~1.65 | 0.2~0.5 | ≤0.04 | ≤0.04 | - | ||

Mechanical Property

| Grade | tensile strength(Mpa) | yield strength (Mpa) | Elongation at cross section(%) | reduction of crosssection area(%) | Shock absorption energy(KV2/J) |

|---|---|---|---|---|---|

| ZG42CrMo | ≥1080 | ≥930 | ≥12 | ≥20 | ≥24 |

| ZG35CrMo | ≥985 | ≥835 | ≥12 | ≥20 | ≥24 |

| ZG38CrMoAl | ≥980 | ≥835 | ≥14 | ≥20 | ≥24 |

| ZG40Cr | ≥980 | ≥785 | ≥9 | ≥20 | ≥24 |

| ZG30Mn2SiCrMo | ≥1500 | ≥1300 | ≥3 | - | ≥24 |

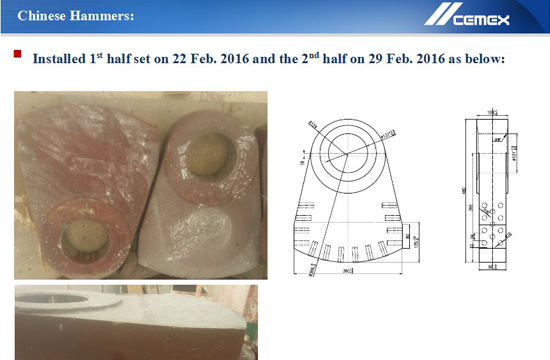

Analysis of the situation of CEMEX using our company's hammers

Learn More

Cement plant limestone crusher hammer use case

Learn More

Warmly celebrate the 10th anniversary of the cooperation between Luoyang Zhili a

Learn MoreThe products we have produced

Flat plate type medium carbon steel grinding table

Flat plate type medium carbon steel grinding table

Flat plate type medium carbon steel grinding table

Ceramic Metal Composite Mill Liner

Ceramic Metal Composite Liner

Sweep

Add friends

Wechat ID

+86-13353997333