Product Introduction

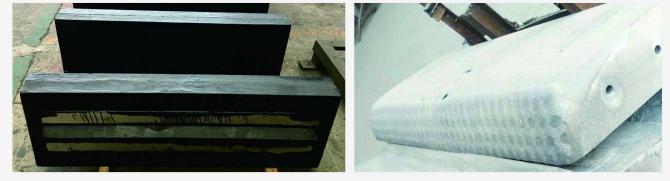

The ceramic-metal composite hammer head/blow bar is formed by melting and casting modified toughened ceramic and high-toughness alloy. The ceramic-metal composite area is distributed in the working part of the wear-resistant part, which can effectively improve the wear resistance of the working surface; at the same time, the hammer head, hammer handle and blow bars body are still made of high-toughness alloy to ensure its safe operation, effectively solve the contradiction between hardness and toughness, and can adapt to various working conditions. It opens up a new field for users to select high-wear spare parts and can create better economic benefits.

Advantages and characteristics

1. Hard but not brittle, tough and wear-resistant, achieving a dual balance of wear resistance and high toughness;

2. Ceramic hardness 2100HV, wear resistance can reach 2-4 times that of ordinary alloy materials;

3. Personalized solution design, more reasonable wear line;

4. Long service life and high economic benefits.

Typical case

A Chinese company started using ceramic-metal composite hammers for its PCF1412 hammer crusher in March 2017 to crush sandstone. The service life is 8.5 months. The original hammers with carbide rods were replaced every 2 to 3 months on average.

A company in Myanmar uses our company's ceramic-metal composite blow bar to crush limestone. When the crushing output reaches 800,000 tons, the wear of the ceramic-metal composite blow bar is reduced by more than 2 times compared with the high-chromium alloy blow bar used before.