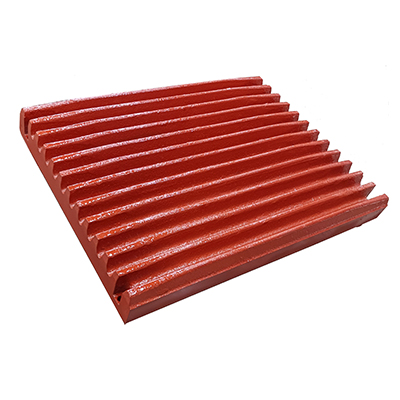

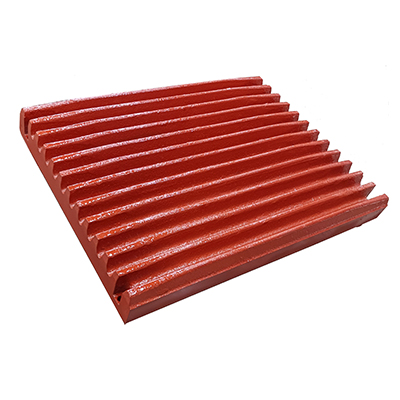

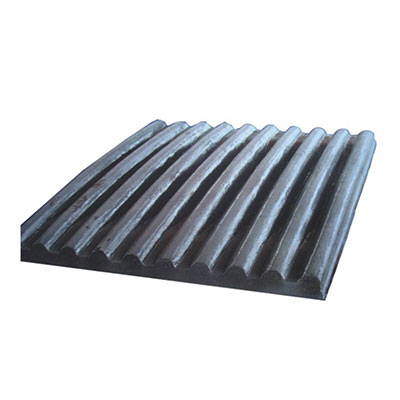

Swing Jaw Plate/Fixed Jaw Plate

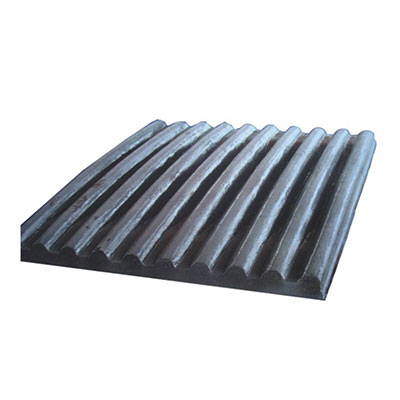

Crusher Plate

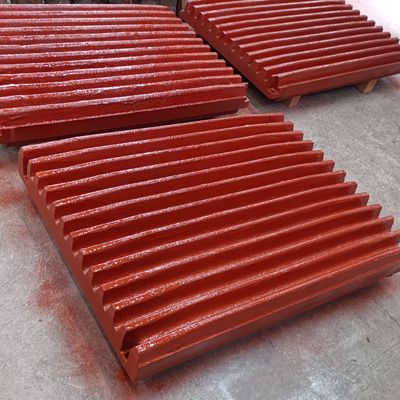

Jaw Plate with alloy bars inserts

Swing Jaw Plate/Fixed Jaw Plate

Jaw Plate

Stone Crusher Jaw Plate

Fixed Jaw Plate|Movable Jaw Plate

Jaw Plate with alloy bars inserts

Mining Jaw Plate

jaw crusher plates

High Chromium Iron Jaw Plate

Jaw Plate Casting

The jaw plate is a key wear-resistant spare part in the jaw crusher. A set of jaw plates consists of a movable jaw plate and a fixed jaw plate.

The jaw plates we produce are made of high manganese steel, ultra-high manganese, alloy steel, high manganese steel insert titanium alloy bars and other materials. Corresponding materials can be selected according to different industrial and mining needs.

Zhili New materials jaw plates have the following features:

1.Designed for maximum operational flexibility;

2.Maximize uptime;

3.Reduce wear;

4.Optimize production;

5.Extend service life.

The wear-resistant solution for jaw crushers depends on whether you are engaged in quarrying, mining or recycling, choose the most suitable jaw plate.

If you don't find the product you need on the website, please email us(info@lyzhili.com), because we are a customized factory for crusher spare parts.

High manganese steel(Mn13Cr2/Mn18Cr2), high manganese steel insert titanium alloy bars, high manganese insert titanium alloy bars and hardfacing, high chromium cast iron, alloy steel, etc.

Feature:

We use proper alloying and and related technological measures to make the crusher Jaw plates’ surface hardness reaches more than 58HRC , during the process of wearing will maintain high hardness and high wear resistance.

Technology process

The working part of hammer head we use the technique of directional solidification to make Cr7C3 type carbide is perpendicular to the part.The macro-hardness and micro hardness of carbide can be improved without reducing thoghness.

Application

Suitable for making wearable spare parts with lower impact load and simpler shape.

Chemical component

Grade | Chemical component% | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | Ni | Cu | S | P | |

| BTMCr15 | 2.0~3.3 | ≤1.2 | ≤2.0 | 14~18 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| BTMCr20 | 2.0~3.3 | ≤1.2 | ≤2.0 | 18~23 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| BTMCr26 | 2.0~3.3 | ≤1.2 | ≤2.0 | 23~30 | ≤3.0 | ≤2.5 | ≤2.0 | ≤0.06 | ≤0.10 |

| 1:Allowed to add microscale V,Ti,Nb,B and Re etc. 2:We will choose grade and specific component according to blow bars’ weight ,thickness and sizes | |||||||||

Mechanical Property

Grade | Surface Hardness | |||||

|---|---|---|---|---|---|---|

Casting condition | Harded condition | Softening annealing condition | ||||

| HRC | HB | HRC | HB | HRC | HB | |

| BTMCr15 | ≥46 | ≥450 | ≥58 | ≥650 | ≥41 | 400 |

| BTMCr20 | ≥46 | ≥450 | ≥58 | ≥650 | ≥41 | 400 |

| BTMCr26 | ≥46 | ≥450 | ≥58 | ≥650 | ≥41 | 400 |

1:There are no exact corresponing value between rockwell hardness(HRC) and brine hardness(HB),so ,this two kind of hardness value can be inspend used 。 | ||||||

Feature

High manganese steel refers to high alloy steels containing more than 10% manganese. The biggest features of high-manganese steel are:

The greater external compressive stress or impact load, the more conducive to the formation of hardened layer, so the higher the wear resistance of the casting;

With the gradual wear of the hardened layer, new work hardened layers will continue to form under the influence of external compressive stress or impact loads. Therefore, it is suitable for making wearable spare parts that are subject to high impact load and wear for a long time, and is widely used in metallurgy, mining, building materials, railways, electric power, coal and other broken grinding equipment.

Chemical component

Grade | Chemical component% | |||||

|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | S | P | |

| ZG120Mn13 | 1.05~1.35 | 0.3~0.9 | 11~14 | - | ≤0.06 | ≤0.04 |

| ZG120Mn13Cr2 | 1.05~1.35 | 0.3~0.9 | 11~14 | 1.5~2.5 | ≤0.06 | ≤0.04 |

| ZG120Mn17Cr2 | 1.05~1.35 | 0.3~0.9 | 16~19 | 1.5~2.5 | ≤0.06 | ≤0.04 |

| 1:Allowed to add microscale V,Ti,B and Re etc. 2:We can produce the other grade high manganese steel hammer according to customers’ requirments 。 | ||||||

Mechanical Property

Grade | Stretch property | Hardness HB | |||

|---|---|---|---|---|---|

| yield strength ReH/Mpa | tensile strength Rm/Mpa | Elongation at cross section % | Shock absorption energyKu2J | ||

| ZG120Mn13 | - | ≥685 | ≥25 | ≥118 | ≤300 |

| ZG120Mn13Cr2 | ≥390 | ≥735 | ≥20 | - | ≤300 |

Attend FICEM 2024 Technical Conference

Learn More

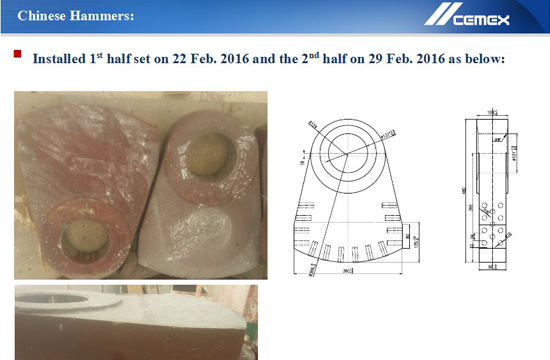

Analysis of the situation of CEMEX using our company's hammers

Learn More

Cement plant limestone crusher hammer use case

Learn More

Philippine customers visit Zhili New Materials

Learn More

Luoyang Zhili cooperated with Lafarge-holcim cement group in India

Learn More

Warmly celebrate the 10th anniversary of the cooperation between Luoyang Zhili a

Learn MoreThe products we have produced

Swing Jaw Plate/Fixed Jaw Plate

Crusher Plate

Jaw Plate with alloy bars inserts

Swing Jaw Plate/Fixed Jaw Plate

Jaw Plate

Stone Crusher Jaw Plate

Fixed Jaw Plate|Movable Jaw Plate

Jaw Plate with alloy bars inserts

Mining Jaw Plate

jaw crusher plates

High Chromium Iron Jaw Plate

Jaw Plate Casting

Jaw Crusher Liners | Jaw Crusher Cheek Plates

Jaw Crusher Toggle Plate

Plates For Crusher

Manganese Jaw plate

Jaw Plate

Bimental Jaw Plate

Swing Jaw Plate/Fixed Jaw Plate

Jaw Plate