D-type shackles

shackles

Rotary kiln Shackles

Bow-shaped shackle

D-type shackles

Bow-shaped shackle

D-type shackles

OEM tailor design

Product name: Rotary kiln Shackles/D-type shackles/Bow-shaped shackle

Production process: Casting,Forging

Material types: 115MA,Low-alloy heat-resistant steel, low-chromium-nickel oxidation-resistant steel,etc.

Applicable industries: Cement, metallurgy, chemical industry, architecture,steel,Papermaking, metallurgy, etc.

Our service:

1. Before sales, we will fully understand the customer's working conditions and recommend the most appropriate material selection to the customer.

2. Provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After sales, we will continue to pay attention to the usage of the product and provide timely help.

If you need detailed technical information of the product or cannot find the product you need on the website, please email us(info@lyzhili.com), because we are a customized factory for heat-resistant steel castings.

D-type shackles include general lifting shackles, marine shackles and ordinary shackles. They are heavy and large in size, and are generally not installed in places where they are not often disassembled. When choosing a shackle, you should pay attention to the safety factor, which is generally 4 times, 6 times and 8 times.

The main shapes of shackles are D-type and bow-shaped, and customized production of other shapes and materials is supported.

Shackles are manufactured in a wide variety of types and sizes. Before choosing the right shackle for application, it is necessary to understand the types of shackles.The shackles come with different pin options, including round pin shackles, screw pin shackles, and bolt-type shackles.

Shackles are available in a variety of material grades, from 8630 alloy to 310 stainless steel, depending on the application.

It adopts a manufacturing method combining alloy steel, die forging and free forging, and is widely used in various industries such as electricity, metallurgy, petroleum, machinery, railways, chemicals, ports, mining, and construction. However, it should be noted that the use of the shackle must not exceed the specified safety load.The metal surface is coated with zinc, nickel, cadmium, composite plating and other coatings to prevent corrosion.

D-type shackle parameters:

Rated load T | A mm | B(Ф) mm | C mm | D(Ф) mm | E mm | F mm | G mm |

| 3 | 42 | 30 | 27 | 60 | 150 | 96 | |

| 5 | 58 | 38 | 34 | 76 | 195 | 126 | 104 |

| 8 | 61 | 40 | 35.5 | 96 | 212 | 133 | 109 |

| 10 | 66 | 45 | 39 | 100 | 235 | 144 | 144 |

| 15 | 70 | 50 | 46 | 89 | 274 | 162 | 159 |

| 20 | 79 | 55 | 51 | 112 | 308 | 181 | 174 |

| 25 | 88 | 60 | 61 | 122 | 329 | 210 | 177 |

| 32 | 100 | 70 | 66 | 138 | 395 | 232 | 215 |

| 40 | 110 | 80 | 75 | 158 | 440 | 260 | 246 |

| 50 | 130 | 90 | 76 | 158 | 468 | 282 | 268 |

| 60 | 130 | 95 | 80 | 178 | 290 | ||

| 80 | 124 | 100 | 92 | 178 | 520 | 308 | 289 |

Attend FICEM 2024 Technical Conference

Learn More

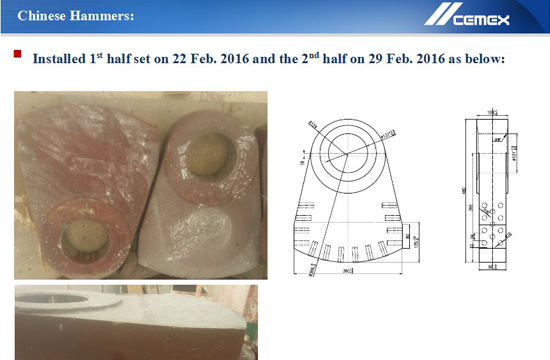

Analysis of the situation of CEMEX using our company's hammers

Learn More

Cement plant limestone crusher hammer use case

Learn More

Philippine customers visit Zhili New Materials

Learn More

Luoyang Zhili cooperated with Lafarge-holcim cement group in India

Learn More

Warmly celebrate the 10th anniversary of the cooperation between Luoyang Zhili a

Learn MoreThe products we have produced

D-type shackles

shackles

Rotary kiln Shackles

Bow-shaped shackle

D-type shackles

Bow-shaped shackle

D-type shackles