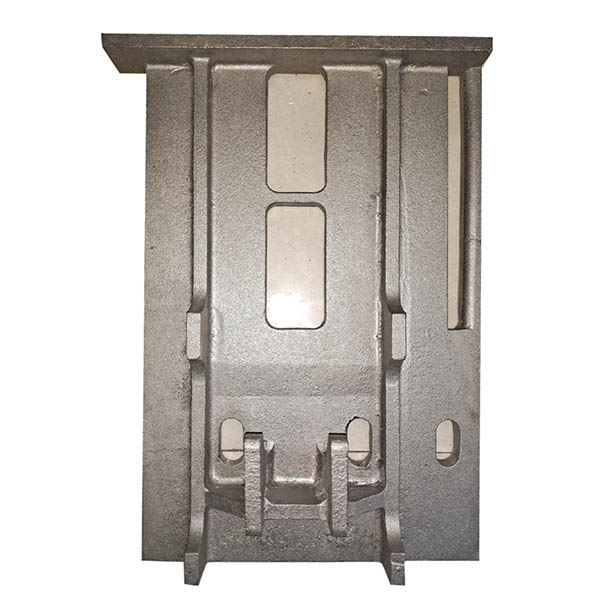

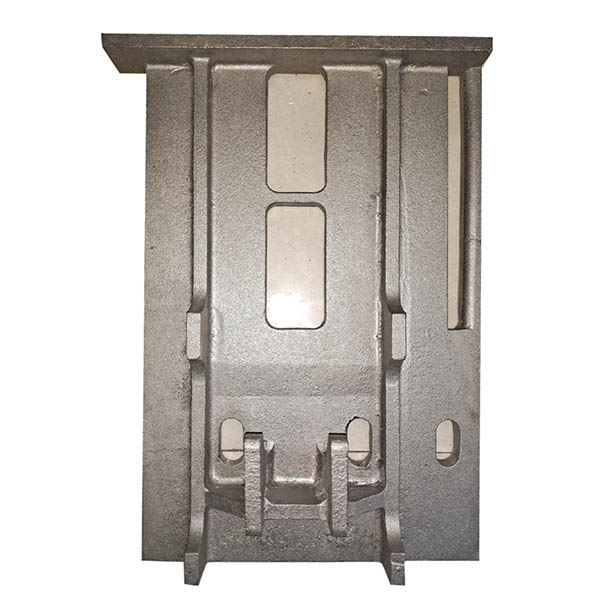

Cooling Grate

Grate Plates

Grate Plates

Grate Plates

Cooler Grate Plates

OEM tailor design

Product name: Grate Cooler grate plates/Heat-resistant steel grate plate/wind board/Cooling Grate

Production process: Precision casting, Sand casting, Lost foam casting, Centrifugal casting

Material types: 1Cr10MoW2VNbN,12Cr1MoV,25Cr2MoVA,12Cr2MoWVTiB,Low-alloy heat-resistant steel, low-chromium-nickel oxidation-resistant steel,etc.

Applicable industries: Cement, metallurgy, chemical industry, steel, pellets, etc.

Application areas: Cement grate cooling machine, manufacturing parts for boilers, steam turbines, power machinery, industrial furnaces, aviation, petrochemicals, etc. that work at high temperatures.

Application scenario: After the cement clinker enters the cooler from the kiln, it is spread on the grate plate to form a material layer of a certain thickness. The cold air blown in passes through the material layer moving on the grate bed in perpendicular directions to quench the clinker, and the clinker can be quenched from 1300-1400℃ to below 100℃ within a few minutes.

Classification by normalized organization: austenitic heat-resistant steel, martensitic heat-resistant steel, ferritic heat-resistant steel and pearlite heat-resistant steel.

Features:

1. The heat-resistant steel grate plate has good wear resistance and long service life, which is more than ten times that of metal screens, 3-5 times that of ordinary rubber plates, and 2-3 times that of stainless steel;

2. It absorbs shock and reduces noise, and the cost is lower than that of metal screen plates;

3. The heat-resistant steel screen plate has good automatic cleaning, and due to its multiple holes, the screening efficiency is high;

4. It has good moisture resistance and wear resistance.

Our service:

1. Before sales, we will fully understand the customer's working conditions and recommend the most appropriate material selection to the customer.

2. Provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After sales, we will continue to pay attention to the usage of the product and provide timely help.

If you need detailed technical information of the product or cannot find the product you need on the website, please email us(info@lyzhili.com), because we are a customized factory for heat-resistant steel castings.

Attend FICEM 2024 Technical Conference

Learn More

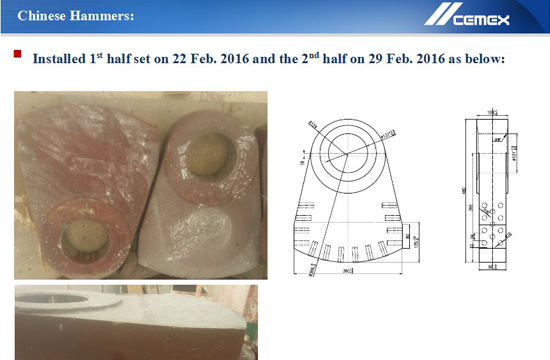

Analysis of the situation of CEMEX using our company's hammers

Learn More

Cement plant limestone crusher hammer use case

Learn More

Philippine customers visit Zhili New Materials

Learn More

Luoyang Zhili cooperated with Lafarge-holcim cement group in India

Learn More

Warmly celebrate the 10th anniversary of the cooperation between Luoyang Zhili a

Learn MoreThe products we have produced

Cooling Grate

Grate Plates

Grate Plates

Grate Plates

Cooler Grate Plates