Low Chromium Steel Balls

High Chromium Steel Balls

CADI Alloy Wear-Resistant Balls

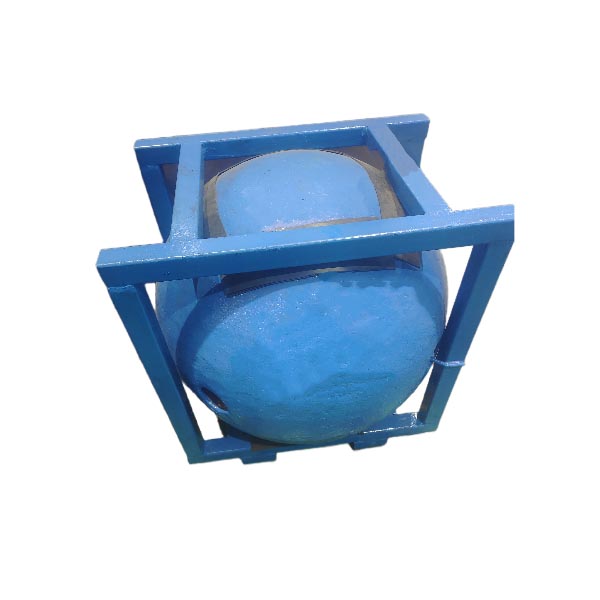

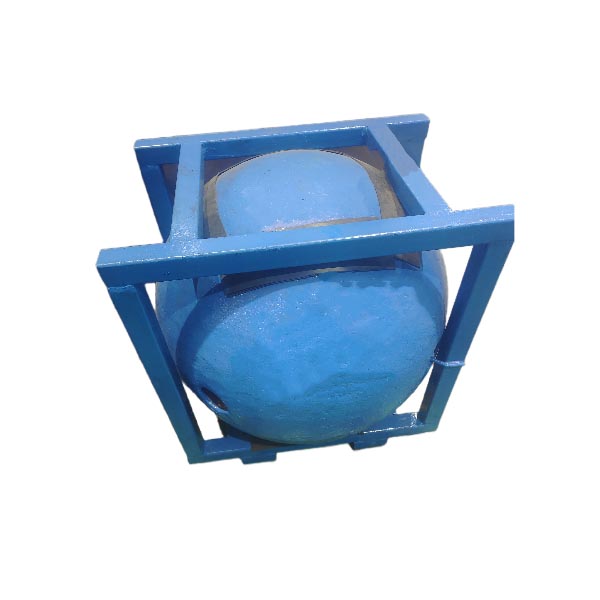

Grinding Balls

Grinding Balls

Grinding Balls

Grinding Media Balls

High Chromium Steel Balls

Balls in Ball mill,SAG Ball mill,Bearings,etc. have different milling effects on materials depending on size, weight and material. Different sizes of steel balls can perform better milling in a certain proportion in the same abrasive silo.

Material types: high chromium, CADI alloy, manganese steel, high chromium cast iron, alloy steel,high manganese steel +TiC alloy bar +wear-resistant welding laye, etc.Applicable materials: Cement, silicate, new building materials, refractory materials, ferrous and non-ferrous metals, glass ceramics, etc.

Our company provides professional matching service for steel ball, and at the same time, we recommend the steel ball material that is most suitable for your working conditions and materials.

Chemical component

|

Grade |

Chemical component % | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | Ni | Cu | S | P | |

| ≥10 | ≤1.2 | ≤2.0 | 14~18 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 | |

Mechanical Property

| Grade | Surface Hardness | |||||

|---|---|---|---|---|---|---|

| Casting condition |

Hardened or hardened stress relief treatment Harded condition |

Softening annealing condition | ||||

| HRC | HB | HRC | HB | HRC | HB | |

| ≥46 | ≥450 | ≥58 | ≥650 | ≤41 | 400 | |

|

1:There are no exact corresponing value between rockwell hardness(HRC) and brine hardness(HB),so ,this two kind of hardness value can be inspend used |

||||||

Chemical component

|

Grade |

Chemical component% | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | Ni | Cu | S | P | |

| 3.0~10 | ≤1.2 | ≤2.0 | 14~18 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 | |

|

1:Allowed to add microscale V,Ti,Nb,B and Re etc. |

|||||||||

Mechanical Property

| Grade | Surface Hardness | |||||

|---|---|---|---|---|---|---|

|

As-cast or as-cast stress Casting condition |

Harded condition | Softening annealing condition | ||||

| HRC | HB | HRC | HB | HRC | HB | |

| ≥46 | ≥450 | ≥58 | ≥650 | ≤41 | 400 | |

|

1:There are no exact corresponing value between rockwell hardness(HRC) and brine hardness(HB),so ,this two kind of hardness value can be inspend used。 2:The hardness in the 40%deepness of casting section should be lower than 92% hardness of surface. |

||||||

Chemical component

|

Grade |

Chemical component % | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | Ni | Cu | S | P | |

| 1.5~3.0 | ≤1.2 | ≤2.0 | 14~18 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 | |

|

1:Allowed to add microscale V,Ti,Nb,B and Re etc. 2: We will choose grade and specific component according to blow bars’ weight ,thickness and sizes |

|||||||||

Mechanical Property

| Grade | Surface Hardness | |||||

|---|---|---|---|---|---|---|

| As-cast or as-cast stress Castingcondition | Harded condition | Softening annealing condition | ||||

| HRC | HB | HRC | HB | HRC | HB | |

| BTMCr15 | ≥46 | ≥450 | ≥58 | ≥650 | ≤41 | 400 |

Attend FICEM 2024 Technical Conference

Learn More

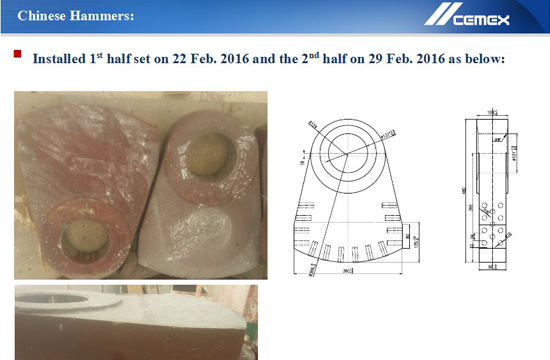

Analysis of the situation of CEMEX using our company's hammers

Learn More

Cement plant limestone crusher hammer use case

Learn More

Philippine customers visit Zhili New Materials

Learn More

Luoyang Zhili cooperated with Lafarge-holcim cement group in India

Learn More

Warmly celebrate the 10th anniversary of the cooperation between Luoyang Zhili a

Learn MoreThe products we have produced

Low Chromium Steel Balls

High Chromium Steel Balls

CADI Alloy Wear-Resistant Balls

Grinding Balls

Grinding Balls

Grinding Balls

Grinding Media Balls

High Chromium Steel Balls