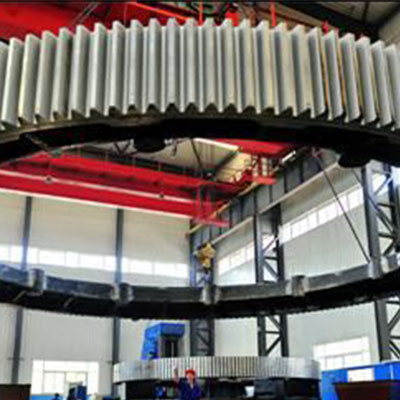

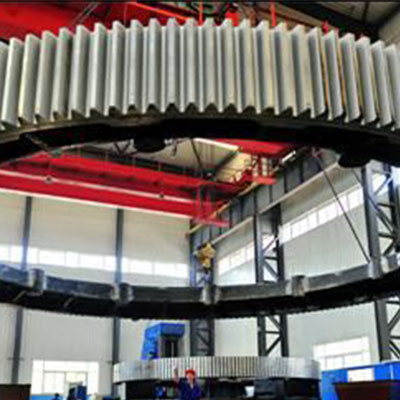

Alloyed high manganese steel gear wheel/Girth Gear

Alloyed high manganese steel gear wheel/Girth Gear

Alloyed high manganese steel gear wheel/Girth Gear

Alloyed high manganese steel gear wheel

Alloyed high manganese steel gear wheel

Alloyed high manganese steel gear wheel

Alloyed high manganese steel gear wheel

The structure of the ball mill gear wheel(girth gear) has different shapes due to different requirements, but from the perspective of the process, the wheel can be regarded as consisting of two parts: the ring gear and the wheel body. According to the distribution form of teeth on the ring gear, it can be divided into straight teeth, helical teeth, herringbone teeth and so on.

If you don't find the product you need on the website, please email us(info@lyzhili.com), because we are a customized factory for crusher spare parts.

Feature and process technology

Usually we use forgings, bar stock, or casting with good toughness that are easy to machine, often using forgings

First normalizing the rough part to improve their machinability and roughing

In the semi-finishing process, the gears are basically formed, after which they are processed to obtain the mechanical properties of the gears. According to the requirements of the working conditions and the materials used ,the quenching and tempering, the carburizing quenching, and the tooth surface high-frequency induction are used. Heat quenching, nitriding and other processes make it possible to obtain the mechanical properties that should be obtained under different working conditions.

Finally, the gears need precision machining .

Steel grades for different working conditions

Medium hard gear (HB220-320): 40Cr, 42CrMo, 40CrNiMo, 38CrMoAl and other medium carbon alloy steels

Hardened gear (HRc56-62): 20CrMnTi, 20CrMnMo, 20CrNiMo, 20CrNi2Mo, 12CrNi3, low carbon alloy steel.

Nitriding gears: 25Cr2MoV, 38CrMoAl

For large diameter (D> 400-600mm) tooth blanks can not be forged, cast steel tooth blanks can be used, generally used ZG45, ZG 40Cr, ZG 42CrMo, ZG 40CrNiMo, ZG 38CrMoAl and other medium carbon alloy steel. The steel composition of the cast steel is equivalent to the chemical composition of the forged steel and only increases the Si content to 0.60-0.80%.

Chemical component

| Grade | C | Si | Mn | Cr | Mo | Ni | V | other |

|---|---|---|---|---|---|---|---|---|

| 40Cr | 0.37- 0.44 | 0.17-0.37 | 0.50-0.80 | 0.80-1.10 | - | - | - | - |

| 42CrMo | 0.38-0.45 | 0.17-0.37 | 0.50-0.80 | 0.90-1.20 | 0.15- 0.25- | - | - | - |

| 40CrNIMoA | 0.37- 0.44 | 0.17-0.37 | 0.50-0.80 | 0.60-0.90 | 0.15- 0.25- | 1.25- 1.65 | - | - |

| 38CrMoAl | 0.35- 0.42 | 0.20-0.45 | 0.30-0.60 | 135- 1.65 | 0.15- 0.25- | - | - | Al0.70-1.10 |

| 20CrMnTi | 0.17-0.23 | 0.17-0.37 | 0.80-1.10 | 1.00- 1.30 | 0.20 0.30 | - | - | TI0.04- 0.10 |

| 20CrMnMo | 0.17-0.23 | 0.17-0.37 | 0.90-1.20 | 1.10- 1.40 | 0.20 0.30 | - | - | - |

| 20CrNi2Mo | 0.17-0.23 | 0.17-0.37 | 1.10- 1.40 | 1.00- 1.30 | 0.20 0.30 | 3.25-3.65 | - | - |

| 12CrNi3 | 0.10-0.16 | 0.17-0.37 | 0.30-0.60 | 120- 1.60 | - | 3.00-3.50 | - | - |

| 25Cr2MoVA | 0.22- 0.,29 | 0.17-0.37 | 0.40- 0.70 | 1.50-1.80 | 0.25 0.35 | - | 0.15-0.30 | - |

Thai Guests Visit Our Factory for Inspection and Exchange

Learn More

Attend FICEM 2024 Technical Conference

Learn More

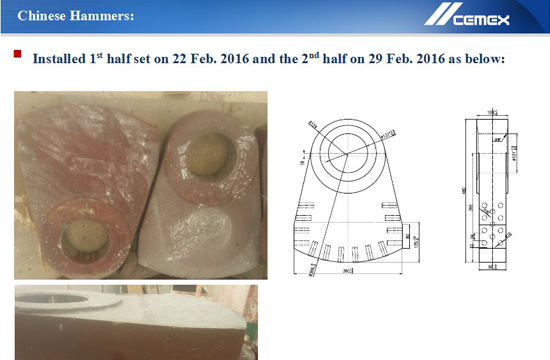

Analysis of the situation of CEMEX using our company's hammers

Learn More

Cement plant limestone crusher hammer use case

Learn More

Philippine customers visit Zhili New Materials

Learn More

Luoyang Zhili cooperated with Lafarge-holcim cement group in India

Learn MoreThe products we have produced

Alloyed high manganese steel gear wheel/Girth Gear

Alloyed high manganese steel gear wheel/Girth Gear

Alloyed high manganese steel gear wheel/Girth Gear

Alloyed high manganese steel gear wheel

Alloyed high manganese steel gear wheel

Alloyed high manganese steel gear wheel

Alloyed high manganese steel gear wheel