Company Introduction

Luoyang Zhili New Materials established in 1992, is one of the world's leading wear-resistant materials processing center, providing high quality wearing parts service for mining, cement, power plant, steel, coal industries, etc.

The company boasts an outstanding team of technical experts, including 13 technical engineers, including five senior engineers, five engineers, and three assistant engineers. The company boasts a highly skilled workforce, including eight graduate students, 15 undergraduates, and 30 associate degree graduates.

The company boasts a modern 18,000-square-meter facility equipped with comprehensive production equipment. All smelting furnaces are medium-frequency induction furnaces, including two 5-ton furnaces, two sets of 3-ton furnaces, two sets of 2-ton furnaces, and two 1-ton furnaces. The company also boasts three stacking welding robots and modern production lines for resin sand, lost foam, and iron sand laminating, with a total annual production capacity of 18,000 tons. Advanced processes such as argon refining, composite inlaying, additive overlay welding, and isothermal heat treatment are employed to ensure stable and superior product performance.The company also has complete machining facilities and testing systems to ensure product quality meets standards.Leveraging our strong technical expertise, stable production capacity, and efficient delivery capabilities, we are committed to becoming our customers' most reliable partner.

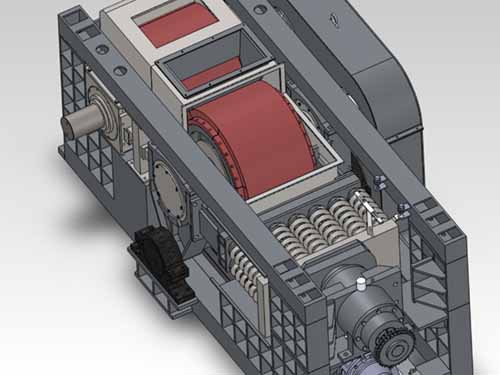

Wear-resistant equipment accessories

By means of our unique knowledge and innovative solutions, we help our customers improve wear-resistance efficiency, reduce the risk of use, and help our customers save a lot of money, which is deeply loved by customers.

✔ China's first domestic manufacturer of bimetal composite hammers.

✔ Cooperating with several famous domestic large-scale cement manufacturers (Conch Cement, Taiwan Cement Corporation, Esheng group, etc.).

✔ Establish long cooperation with Posco, Cemex.

✔ In 2011, we have the honor to win "China top cement industry suppliers";.

✔ Our company win the honore of The third China Wear-resistant Material "Golden globe".

✔ In 2013, we cooperated with the world first cement group Lafarge.

✔ We established long time cooperation with Mexican Cement Group Cemex.

✔ In 2017, in the sharp competition, the company successfully obtained the official authorization of HARDAX wear-resistant steel plate from SSAB and became the Hardox Wear Product Service Center.

✔ 2018 Reached cooperation agreements with several Middle Eastern cement plants.

✔ 2019 In order to expand production, shorten delivery time, and meet the order needs of domestic and foreign customers, the company established a branch factory in Yunnan and set up a new company.

✔ 2020 The ceramic metal composite series products developed by the company were successfully launched.

✔ 2023 We independently developed a heat resistant and wear-resistant technology - ceramic composite matrix reinforcement technology.

✔ 2024 After strict review by the international certification body GICG, the company successfully passed the ISO quality management system certification and obtained the certification certificate.

overview of factory equipments

detection device

Laser cutting equipment

Machining equipment

Machining equipment

3D mould cutting equipment

workroom for shipment

Today, we are still working hard to provide more after-sales services and product choices for more and more customers, to meet the needs of all smashing equipment and wear-resistant equipment in the market now.