Roller press studs

High-chromium cast studs

Roller press studs

Alloy steel studs

High-chromium cast studs

Alloy steel studs

Global Sales OEM tailor design

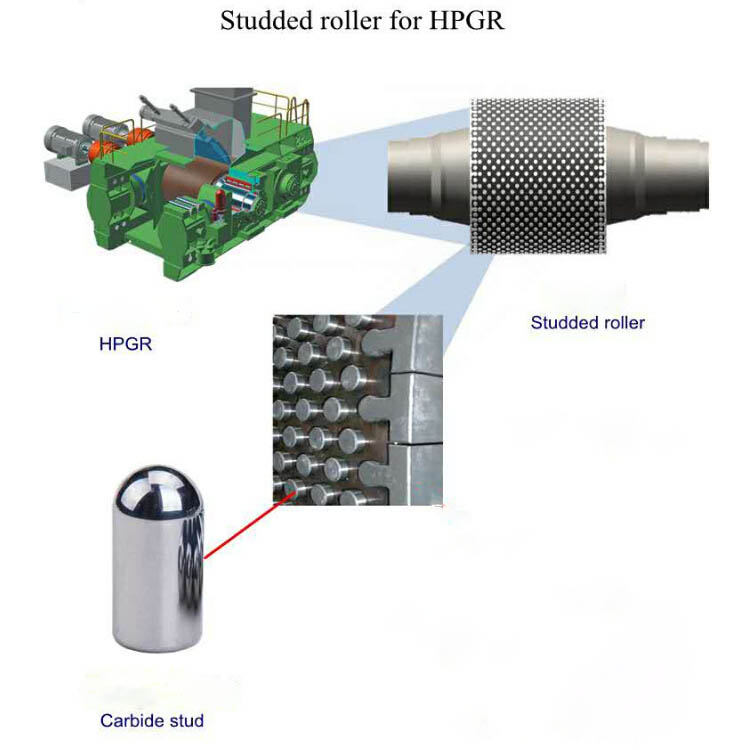

Product name: Roller press Studs/Studs for roller press/Wear-resistant studs

Production process: Casting、Forging

Applicable machines: Roller press,High pressure grinding roller(HPGR)

Material types: High chromium cast iron, alloy steel, Carbide composite nails

Applicable industries: Cement, chemicals, electricity, mining,metallurgy, building materials, refractory materials

Adaptable materials: Cement,Limestone, slag, Iron Ore,coke, coal and other materials

Our service:

1. Before sales, we will fully understand the customer's working conditions and recommend the most appropriate material selection to the customer.

2. Provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After sales, we will continue to pay attention to the usage of the product and provide timely help.

4. Ensure that the quality of the purchased components is impeccable, and the technical parameters absolutely meet national standards.

5. Provide free quotation, worldwide sales, short delivery cycle, low price.

If you need detailed technical information of the product or cannot find the product you need on the website, please email us(info@lyzhili.com), because we are a customized factory for roller press spare parts.

Roller press nails are the core wear-resistant parts of the roller surface of the roller press (Roller Press), which are used to grind high-hardness materials (such as cement clinker, ore, etc.). It has the following functions:

1. Crushing and grinding: high-efficiency grinding is achieved through high-pressure extrusion of materials.

2. Protect the roller surface: reduce direct wear on the roller surface and extend the life of the roller sleeve.

3. Optimize energy consumption: reduce grinding power consumption (30%-50% energy saving compared to ball mill).

The nails we produce have high wear resistance, impact resistance, high temperature resistance, and easy replacement.

Frequently Asked Questions

Q1: How long is the life of the nail?

A: It depends on the hardness of the material, usually:

Cement clinker: 8,000-12,000 hours

Iron ore: 3,000-5,000 hours (tungsten carbide nails can be extended to 10,000 hours).

Q2: Can the worn nails be repaired?

A: High chromium cast iron nails can be repaired 1-2 times by surfacing welding, and tungsten carbide nails cannot be repaired.

Q3: How to reduce the fracture of cast nails?

A: Choose alloy steel with higher toughness (such as 42CrMo) and control the overload of the roller press.

Attend FICEM 2024 Technical Conference

Learn More

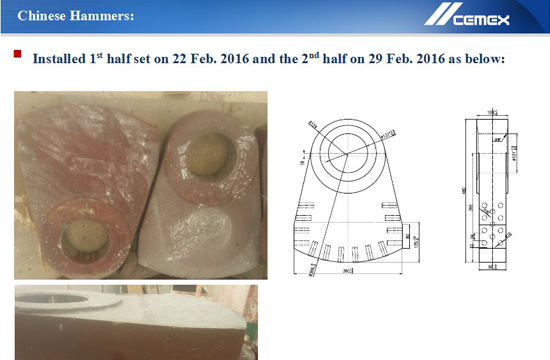

Analysis of the situation of CEMEX using our company's hammers

Learn More

Cement plant limestone crusher hammer use case

Learn More

Philippine customers visit Zhili New Materials

Learn More

Luoyang Zhili cooperated with Lafarge-holcim cement group in India

Learn More

Warmly celebrate the 10th anniversary of the cooperation between Luoyang Zhili a

Learn MoreThe products we have produced

Roller press studs

High-chromium cast studs

Roller press studs

Alloy steel studs

High-chromium cast studs

Alloy steel studs