The jaw plate is a key wear-resistant spare part in the jaw crusher. A set of jaw plates include movable jaw plate and a fixed jaw plate.

Types of jaw plates

Our jaw plates optional materials:high manganese steel, super high manganese, alloy steel, high manganese steel insert titanium alloy bars and other materials.High manganese steel material has high impact toughness and good work hardening ability, more safe and reliable. However, its initial hardness is low and it is not wear-resistant under low impact and the wear conditions of sharp abrasive particles. Under this circumstance, Luoyang ZHILI developed high manganese steel insert titanium alloy bars jaw plates to improve the wear resistance and increase its service life.

High manganese steel insert titanium alloy bars jaw plate

High manganese steel insert titanium alloy bars jaw plate adopts out-of-furnace refining and integral pressure casting technology. It is cast and processed by inlaying carbide bars on the working surface of the jaw plate.The alloy bar is made of steel-bonded cemented carbide suitable for the heat treatment process of high manganese steel. The main wear-resistant particles are tungsten carbide (WC) and titanium carbide (TiC). The binder is alloy steel. It is made by powder metallurgy and has high hardness, high wear resistance and certain impact toughness. The alloy bars can be placed in areas that require wear resistance as required to resist cutting by hard materials, thus showing excellent wear resistance.

High manganese steel insert titanium alloy bars jaw plate produced by our company

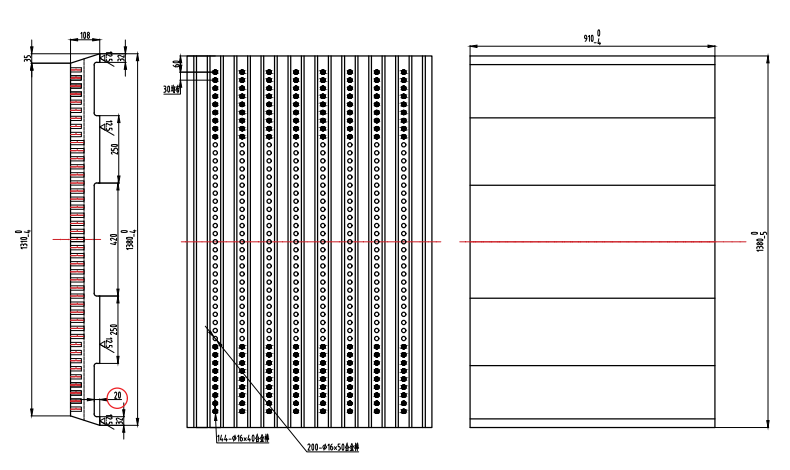

Design drawings of high manganese steel insert titanium alloy bars jaw plate

Adaptable materials: river pebbles, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, etc.

We can provide you with various brands of Jaw crusher spare parts , also can customize and produce according to your working conditions.