Ceramic lining is a material with alumina (AL2O3) as the main body, supplemented with other ingredients, and sintered at a high temperature of 1700°C. It is widely used in coal transportation, material transportation systems, powder making systems, ash removal, dust removal systems and other mechanical equipment with high wear in thermal power, steel, smelting, machinery, coal, mining, chemical, cement, port terminals and other enterprises. Different types of products can be selected according to different needs.

The scraper conveyor for mining uses an open chute as a bearing component for coal, waste rock or materials. The scraper is fixed on the chain (forming a scraper chain) as a traction component to complete material transportation. The mining scraper conveyor consists of a head, a middle part, a tail, a scraper chain and ancillary devices (coal baffles, coal shovels, etc.). The middle part is connected by a transition trough and a multi-section middle trough. The machine trough is divided into upper and lower troughs by a wear-resistant lining, and a scraper chain is installed in the trough.

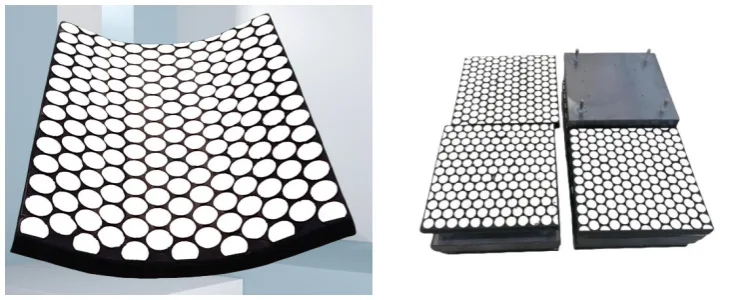

Zhili New Materials mining ceramic wear-resistant lining produced are made of extremely hard ceramic with unparalleled wear resistance, while the rubber can effectively suppress the impact that may break the ceramic rods. The elastic rubber matrix wrapped around the ceramic rods is heat-vulcanized and has excellent adhesion. The mining ceramic conveyor wear-resistant lining is designed to integrate seamlessly with existing applications, with the option of installing studs on the backing plate, fixing it through countersunk holes molded into the lining, or connecting it by welding.

Our products have the following features:

1. Wear resistance: Alumina corundum ceramics, with a hardness of HRA85 or above, are 271.5 times more wear-resistant than manganese steel;

2. Impact resistance: The toughened ceramic formula ensures that the ceramics are not easy to break, and the unique spherical design and buffer layer can resist the impact of large pieces of materials;

3. High temperature resistance: It can operate at 0℃-250℃ for a long time;

4. Acid and alkali resistance: The rubber adopts a new formula of acid and alkali resistant rubber, which can resist weak acids and weak alkalis;

5. Anti-falling: The ceramic rubber steel plate is vulcanized as a whole, and the combination is very strong; each piece of ceramic has a penetrating bolt passing through the bottom steel plate, which is firmly welded, double insurance;

6. Easy installation and replacement: It is provided with a whole liner, which is convenient for replacement and installation, and reduces after-sales service;

7. Reduce maintenance: Wear resistance greatly reduces the frequency of maintenance, saving costs and labor.

If you need it, you can contact us, we will provide you with perfect service around the clock.