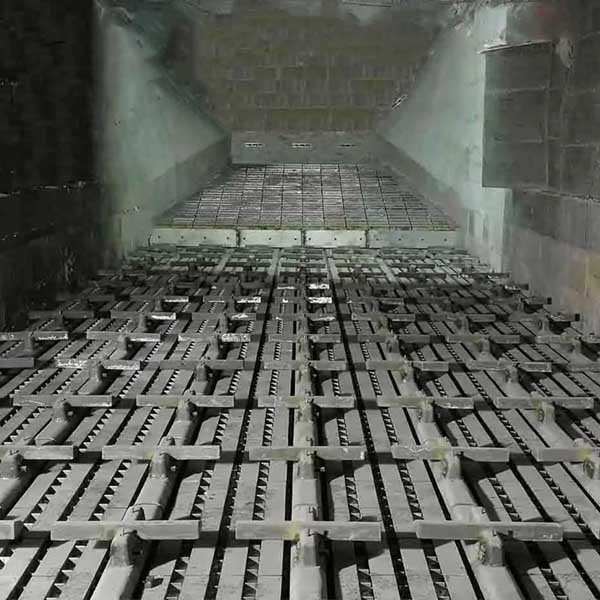

The grate plate is an important part of the cross-bar grate cooler. It is used to support the clinker and allow the cooling air to enter the clinker layer from the grate holes on the grate plate, so that the clinker can be evenly distributed on the grate bed, exchange heat with the clinker, and take away the heat of the clinker, thereby realizing the cooling of the clinker. The structure of the grate plate and the distribution of the grate holes directly affect the circulation effect of the cooling air and the cooling efficiency of the clinker.

The clinker temperature in the grate cooler is as high as 1000℃ or more. The grate plate needs to work for a long time in a high temperature environment. Therefore, the grate plate is required to have good heat resistance and thermal fatigue resistance, and can withstand the test of high temperature without deformation, cracking and other problems. The clinker moves and rubs continuously on the grate bed, causing wear on the surface of the grate plate. At the same time, the hard particles in the clinker will also impact and wear the grate plate. The grate plate needs to have high hardness and wear resistance to ensure its service life. The chemical components in the clinker may chemically erode the grate plate. For example, the alkaline substances in the clinker may react chemically with certain components in the grate plate, resulting in corrosion and damage to the grate plate. The grate plate needs to have a certain resistance to chemical erosion.

The grate plate will be made of wear-resistant materials such as high-chromium cast iron, nickel-hard cast iron, and heat-resistant alloy steel. These materials have high hardness and wear resistance and can withstand the wear and impact of clinker. Zhili New Materials Company can produce grate plates of all the above materials, and the service life of our grate plates is more than 1.5 times that of other companies. There are usually a large number of grate holes distributed on the grate plate to allow cooling air to pass through and cool the clinker. The shapes of the grate holes are round, square, rectangular, etc., and grate holes of different shapes have different effects on the circulation of cooling air and the distribution of clinker. For example, the circulation resistance of the circular grate hole is small, which is conducive to the uniform distribution of cooling air; the square or rectangular grate hole can better adapt to the structural design of the grate plate and improve the strength of the grate plate. The grate plates are usually connected by bolt connection, welding or clamping. Bolt connection is convenient for installation and removal of grate plates, and is convenient for maintenance and replacement; welding connection has high strength and can ensure the firmness of the connection between grate plates, but it is difficult to disassemble; the clamping method is between the two, with a certain connection strength and is also easy to install and disassemble.