The ball mill liner is an important accessory for protecting the inner wall of the mill. It has the functions of improving grinding effect, production efficiency and extending the service life of the mill. The ball mill liner needs to be designed according to the material to be ground and the different types of grinding. The shape of the ball mill liner is different for different types of mills. By changing the shape of the mill liner, the movement state of the grinding medium in the cylinder can be effectively adjusted to achieve different grinding purposes.

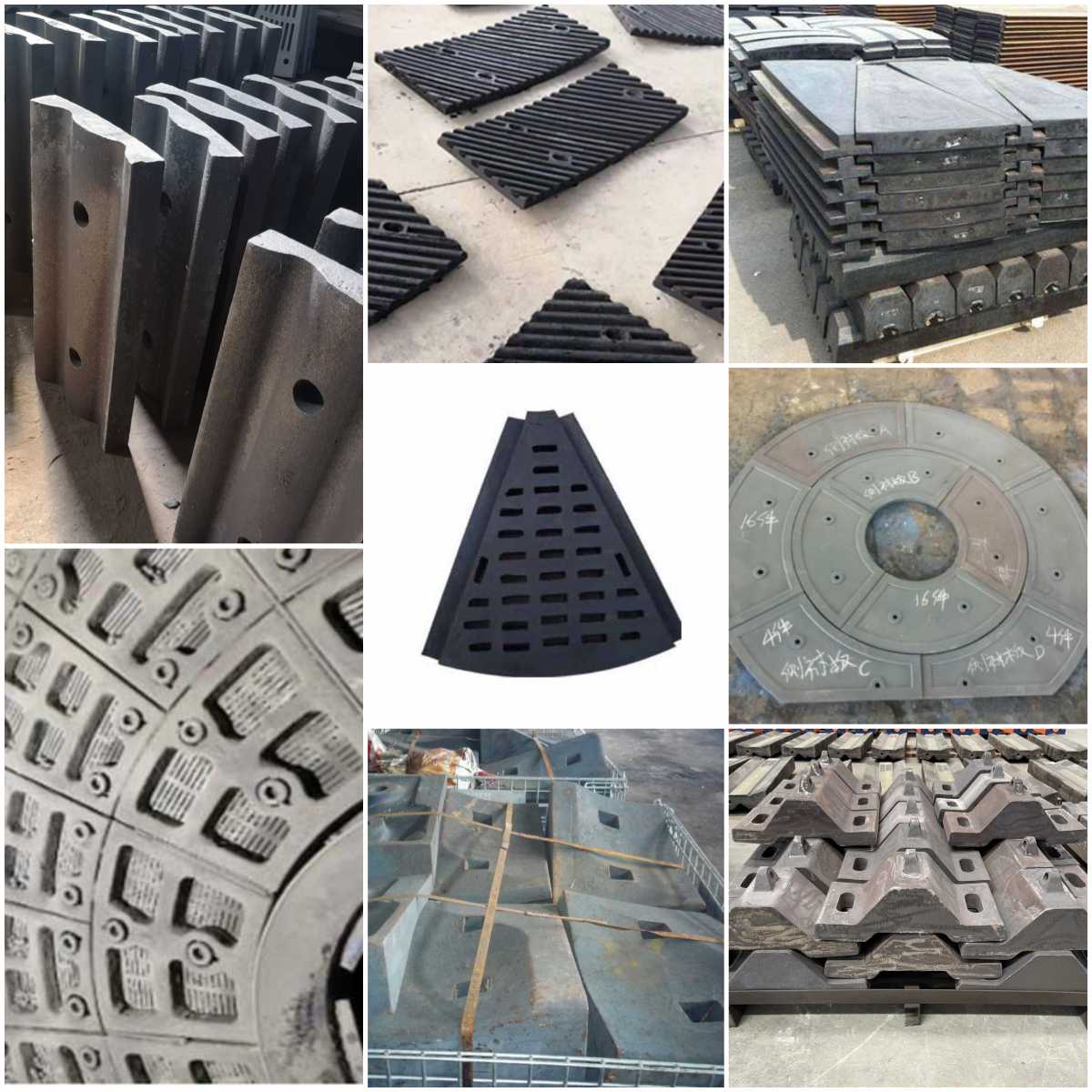

The ball mill liner is divided into two parts: the ball mill cylinder and the end cover. The ball mill cylinder part can be composed of a pressure strip liner, a corrugated liner, a flat liner, a graded liner, a hemispherical liner, and a T-bolt. The end cover part is composed of an end liner, a grating plate, an end strip, a step liner, and a T-bolt.

Flat liner: The surface is flat or patterned, and the grinding body is lifted by friction. The impact crushing of large pieces of material is weak, and the grinding effect is strong. It is suitable for fine grinding bins.

Rib lining: a rib with a semicircular or trapezoidal cross section is cast on the flat lining. The rib has the same function as the pressure strip, and its structural parameters are similar to those of the pressure strip lining. The rib and the flat lining are a whole. When the rib needs to be replaced after being worn, the flat lining part is also scrapped, but the rib lining has greater rigidity than the pressure strip lining.

Pressure strip lining: It is composed of a flat lining and a pressure strip. The pressure strip is higher than the lining, which can increase the lifting height of the grinding body and enhance the impact force on the block material. It is suitable for the coarse grinding bin, but there is a problem of uneven ball carrying. It is not suitable for mills with higher speeds.

Step lining: The surface of the lining is inclined, and it forms a step after installation. It can increase the thrust on the grinding body, make the lifting height of the grinding body on the same layer uniform, and prevent the grinding body from sliding and wearing. It is suitable for the coarse grinding bin.

Corrugated lining: The wave crest and pitch are small, suitable for fine grinding bins and coal mills.

Hemispherical liner: suitable for crushing bin, can make the movement trajectory and distribution of grinding body more reasonable, reduce mutual impact and wear between grinding bodies, and improve grinding efficiency.

End liner: installed on the end cover of grinding head or cylinder end cover, used to protect the end cover from wear.

Grading liner: can automatically grade steel balls, so that steel balls of different diameters are distributed in the appropriate position in the mill to achieve more efficient grinding, often used in occasions where precise control of grinding particle size is required.