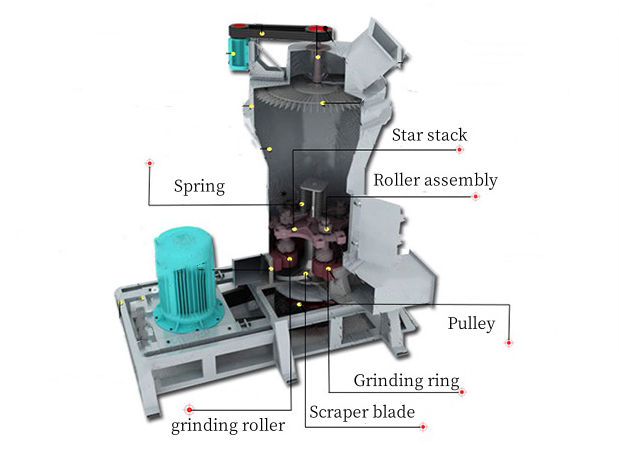

Raymond mill has been widely used in many industries due to its efficient grinding and stable performance. The efficient grinding of Raymond mill is based on a set of ingenious mechanical structures and physical effects. Its core components include grinding rollers, grinding rings and scrapers.

When working, the material to be crushed is added into the machine from the feed hopper on the side of the machine cover. The grinding roller device is hung on the plum blossom frame of the main machine. Driven by the motor, the plum blossom frame revolves around the vertical axis, and the grinding roller itself rotates. Due to the centrifugal force during rotation, the grinding roller swings outward and presses tightly on the grinding ring. The scraper scoops up the material and sends it between the grinding roller and the grinding ring. Under the rolling and crushing of the grinding roller, the material is gradually crushed.

After the material is ground, the fan blows air into the main housing to blow up the powder. The analyzer placed above the grinding chamber begins to work and sorts the powder. Due to its own gravity and the action of the analyzer, the material with too coarse fineness falls into the grinding chamber for re-grinding; the powder with the fineness that meets the specification enters the cyclone collector with the wind flow. In the cyclone collector, the powder is separated from the air flow due to the action of centrifugal force and gravity, and is discharged through the powder outlet after collection, which is the finished product. The airflow returns to the fan through the return air duct at the upper end of the large cyclone collector to form a circulating air path, and the entire air path is in a negative pressure state. The increased air volume of the circulating air path is discharged through the exhaust gas duct between the fan and the main engine, and enters the small cyclone collector for purification to reduce dust emissions and protect the environment.

This working principle enables the Raymond mill to efficiently grind various materials into powders of the required fineness, and through the synergy of the analyzer and the fan, the fineness of the finished product can be precisely controlled.

As an excellent manufacturer of grinding equipment accessories, our company has also conducted in-depth research on Raymond mill accessories. We can produce Raymond mill rollers, grinding rings and scrapers, etc. The wear-resistant parts we produce are well received by customers. Customer reviews are our "navigator" for development, helping us expand the market and increase brand awareness. They help us accurately point out the shortcomings of our products or services, prompting us to make timely improvements, optimize operational strategies, and constantly calibrate our direction on the development path to move forward steadily.