How to improve the service life of high manganese steel blow bars?

In response to customers' desire to improve the output and service life of blow bars, our company provides two solutions, which have been used by customers and have achieved good results.

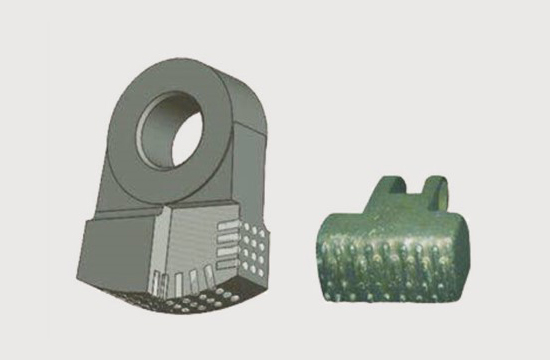

1. Embed Titanium Alloy Bars(TiC) inside the working part of high manganese steel blow bars

The blow bars with alloy bars embedded has a service life of more than 1.5 times that of the blow bars without alloy bars embedded.

When the high manganese material bear large impact force from Stone, its surface hardening quickly and forms the wear resistance surface layer. The insert hard alloy rod had good performance anti-friction ,hardness & toughness. After embedding alloy bars inside high manganese steel Blow Bars, their service life can be increased by more than 1.5 times.

From this section , you can see the blace point is the ally bars ,they conbination with bese material for 100%,don’t worry for falling or pulling out during using.

2. Hard alloy is welded on the surface of high manganese steel blow bars

Our company's hard alloy welding technology has been widely used in blow bars, hammer heads, rotors and other products. This technology can effectively extend the service life of accessories and increase the output of equipment.

Blow Bars : Mn18Cr2 Insert Alloy Bars & Hardfacing