Hammer crushers can be widely used in mining, cement, construction and other fields. In the mining field, hammer crushers are usually used for the initial crushing of mined ore. In the cement field, hammer crushers are often used in the stone crushing process of cement production lines. In the construction field, hammer crushers can be used to crush waste materials such as concrete and bricks.

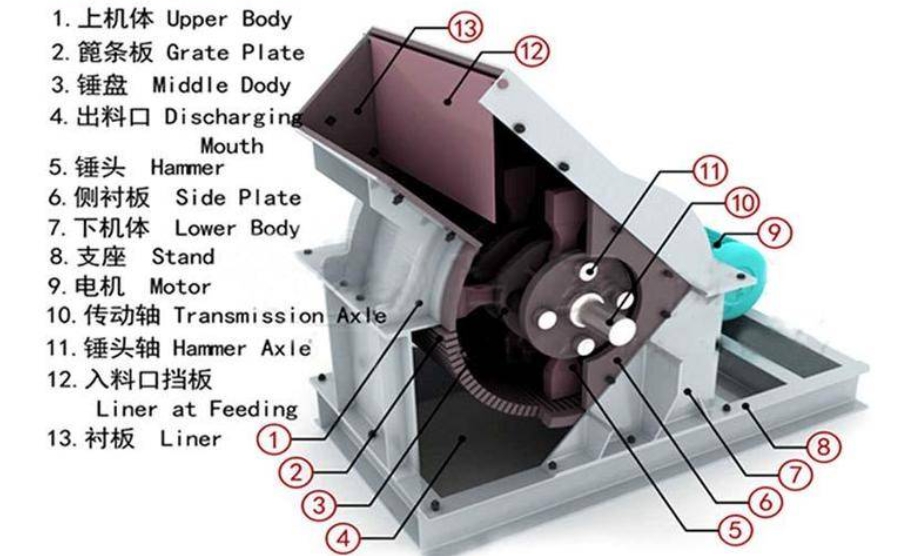

Hammer crushers are mainly composed of casing, rotor, hammer head, liner, screen plate and other parts.

1. Casing

The casing of the hammer crusher consists of the lower body, the rear upper cover, the left wall and the right wall, which are connected together by bolts. The inner wall of the casing is inlaid with lining plates, and a feed port is opened on the top to facilitate the replacement of the lining plates after wear.

2. Crusher Rotor

The rotor is the main working part of the hammer crusher. It consists of the main shaft, hammer plate, pin shaft and hammer head. The hammer head is suspended on the hammer plate through the pin shaft, and the main shaft is supported on the casing through the self-aligning rolling bearing. The rotor rotates at high speed under the drive of the motor, driving the hammer head to crush the material.

Crusher rotor produced by our company

3. Spindle

The spindle is the most important part of the hammer crusher that supports the rotor. It bears the weight and impact force of the rotor and hammer head, so the material of the spindle needs to have high toughness and strength. The spindle is made of high-quality alloy steel and is processed and tempered by ultrasonic flaw detection.

4. Hammer plate

The hammer plate of the hammer crusher is used to hang the hammer head. During the operation of the hammer crusher, the hammer plate will inevitably be impacted and rubbed by the ore, so the hammer plate must have a certain degree of wear resistance.

5. Hammer head

The hammer head is the most important working part of the hammer crusher. The quality, shape and material of the hammer head determine the production capacity of the hammer crusher. The kinetic energy of the hammer head is proportional to the weight of the hammer head. The heavier the hammer head, the greater the kinetic energy and the higher the crushing efficiency. Common hammer head materials include high chromium alloy, high manganese steel, high manganese steel inlaid alloy rod, high manganese steel + surfacing, ceramic composite, etc.

Crusher hammer head produced by our company

The hammer crusher uses the hammer head to hit the ore at high speed. The ore has great speed and kinetic energy in an instant. In order to prevent the wear of the frame, a liner is made on the inner wall of the frame. The liner is mostly made of high manganese steel or high chromium casting, which ensures the superior wear resistance and impact resistance of the liner.