一.Technical Introduction

Cemented carbide is recognized as the best wear-resistant material in the industry, known as "industrial teeth", with excellent Different hardness, red hardness and wear resistance.

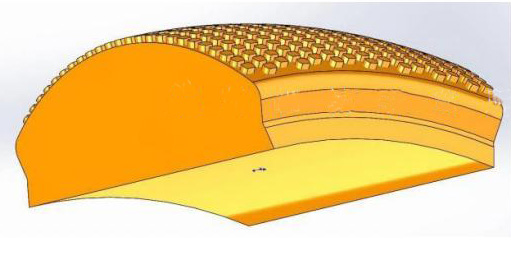

YDFH technology is based on many years of wear-resistant surfacing achievements of the project team .Solved the technical problem of metallurgical bonding between cemented carbide and steel substrate by welding, greatly improved the reliability of the bonding between cemented carbide and substrate, formed the inlay welding structure and metallurgical bonding by combining the alloy stud and surfacing technology, the alloy stud has the role of skeleton pinning, the surfacing material and the alloy stud have the soft and hard combination, has good impact resistance, good surface integrity, and improves the wear resistance and service life of the product, And realize renewable repair to improve product service life.

The technology has the following technical features:

1. It can ensure the integrity of the surface when foreign matters enter, and quickly restore the size, with good surface integrity.

2. The stud can be welded, and the stud is partially worn and peeled off. The stud can be replanted by overlaying, which is convenient quick!

3. The alloy column nail plays a role of skeleton nailing in the parts, and the surface layer is soft and hard within a certain thickness, with good Good impact resistance.

4. It can play the role of high wear-resistant material to the greatest extent, and the hardness of the surfacing material matched with the alloy stud is HRC64-67;

5. YDFH technology can select different alloy stud types and base materials according to working conditions.

二.Alloy stud surfacing welding vertical mill roller introduction (technical code: YDFH)

Alloy stud surfacing welding vertical grinding roller。The grinding roller of the vertical mill is designed according to the working conditions and the wear resistance curve of the product through powder metallurgy technology in the wear zone area Combined with surfacing welding technology, special welding materials are used to form inlaid welding structure and metallurgical combination to improve product wear resistance Sex and service life, and achieve regenerative repair to improve product life. These rollers are suitable for extreme Under harsh working conditions, it can replace ceramic rollers currently on the market. Information about common surfacing rolls, ceramic rolls and YDFH rolls The information is shown in the table below:

Table 1 Characteristics of different types of vertical mill rollers

Item | Hardfacing roller | Ceramic roller | YDFH Roller |

shaping method | hardfacing | Inlay casting |

Inlay welding |

Wearing layer thickness | 40~100 | 40~60 | 40~60 |

Main hard phase of hard surface | NbC, Cr7C3,VC,MoC And so on | ZTA Ceramic | TiC、NbC、Cr7C3、VC、MoC and so on |

Repair-ability | No | No | Can repair 3-5 times |

Roller surface integrity | Restorable to original size | Unrecoverable | Restorable to original size |

Roller Servicing life under Typical working condition | 8000 hours | 16000 hours | 15000-20000 hours |

Cost performance | High under normal working condition | Low | High under under harsh Working conditions |

Typical local legend of roller surface |

|

| |

Alloy stud surfacing welding vertical grinding roller has the following characteristics:

1.The base material is made of high-strength and high-toughness alloy cast steel, which can be welded; 2 The corresponding alloy studs can be selected according to the working conditions. The alloy studs have good wear resistance and are comparable to ceramic and weldable;

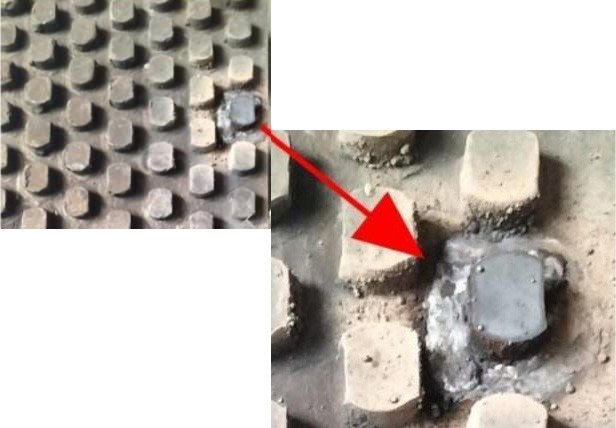

2.In case of peeling of alloy studs under abnormal circumstances, the studs can be replanted by surfacing welding, which is convenient and quick;

3.The alloy stud forms a pinning effect in the welded structure, which further improves the durability of the alloy stud and the surfacing layer. Grinding and reliability.

4.The surface of the grinding roller has good peeling resistance and good integrity.

The design drawing and the finished product of the alloy stud vertical grinding roller are shown in the following figure:

Figure 4 Split type and overall view of vertical mill roller with alloy stud surfacing welding

Figure 5 Alloy stud surfacing welding vertical mill roller stud plant and repair welding

三、The extrusion roller of alloy stud surfacing roller press is developed and industrialized by YDFH technology

The extrusion roller of the roller press is designed according to the working conditions and the wear resistance curve of the product. In the wear area, the powder metallurgy technology and surfacing technology are combined, and the special welding materials are used to form the inlay welding structure and metallurgical combination, improve the wear resistance and service life of the product, and achieve the regenerative repair to improve the service life of the product. This type of roller is suitable for extremely severe working conditions and can replace the alloy roller and other products on the current market. The relevant information of common alloy roll, adhesive column nail roll and YDFH roll is shown in Table 2 below:

Table 2 Characteristics of extrusion rolls of different types of roller

item | Alloy rolls | Glue column nail roll | YDFH Roll |

shaping method | Pouring | Punching and gluing | Inlay welding and metallurgical bonding |

Main hard phase of hard surface | Cr7C3、VC 、MoC And so on | TiC 、WC | TiC、NbC、Cr7C3、VC、MoC and so on |

Repairability | No | No | Can repair 3-5 times |

Roll surface integrity | Unrecoverable | Unrecoverable | Restorable to original size |

Base material and stud type |

single |

single | Many and can be changed according to working conditions |

Cost performance under harsh working conditions |

Low |

Low |

High |

Typical local legend of roller surface |

|

|

|

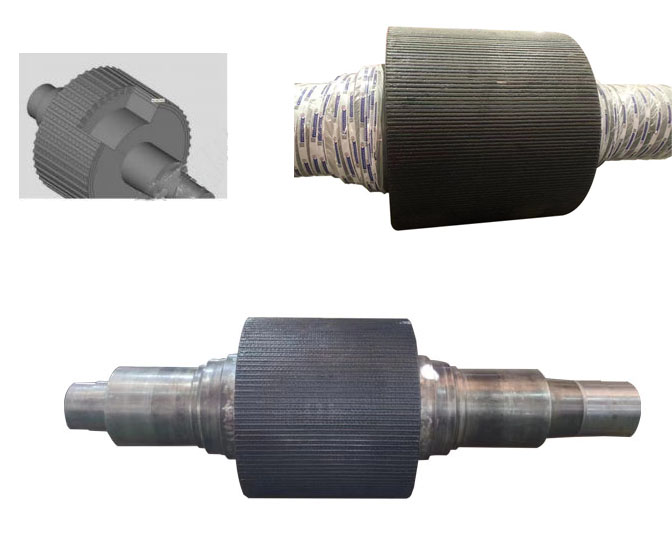

The extrusion roller of alloy stud surfacing roller press has the following characteristics:

6. The base metal is high-strength and high-toughness alloy cast steel, which can be welded;

7. The corresponding alloy studs can be selected according to the working conditions. The wear resistance of the alloy studs is good, comparable to that of ceramets, and can be welded;

8. In case of peeling of alloy studs under abnormal conditions, the studs can be replanted by overlaying, which is convenient and fast;

9. The alloy stud forms a binding effect in the inlay welding structure, further improving the resistance of the alloy stud and the surfacing layer Abrasion and reliability

10. The surface of grinding roller has good peeling resistance and integrity; The integrity of the roll surface can be guaranteed when foreign matters enter, Quickly restore size.

The design drawing and finished products of the extrusion roll of the alloy pin roller press are shown in the figure below

If you need more product information, please send us an email (info@lyzhili.com ) and we will reply you as soon as possible.