If you are engaged in cement, coal, mining, recycling and other industries, you must be concerned about the service life of wear-resistant spare parts. Are you also troubled by the following problems: short life of equipment accessories, difficulty in meeting production needs, frequent shutdowns and repairs are time-consuming and labor-intensive? This article will introduce a new type of wear-resistant material - ceramic particle reinforced iron-based composite castings, to solve these problems!

Industry Status

Wear-resistant iron-based components such as blow bars, hammer heads, grinding rollers, grinding balls and grinding discs are widely used in key equipment in cement, mining, coal, chemical, recycling and other industries. Their main function is to improve the efficiency of grinding and crushing. Taking the hammer heads in the mining industry as an example, their service life is usually less than one month, and the annual domestic consumption reaches 150,000 tons; and the annual cast iron grinding rollers required by industries such as cement are more than 250,000 tons. Traditional wear-resistant cast iron components generally use ordinary cast iron, high chromium cast iron, ductile iron, vermicular cast iron, etc., but most of these traditional wear-resistant steel materials currently have a common problem, that is, wear resistance and toughness restrict each other, resulting in a short service life under actual working conditions, making it difficult to meet production needs, and frequent shutdowns for maintenance are time-consuming and labor-intensive, increasing production costs. Therefore, it is urgent to develop new wear-resistant castings.

New wear-resistant materials

Ceramic particle reinforced iron-based composite castings are wear-resistant castings made of new composite materials. They can give full play to the high wear resistance of ceramic reinforcements and the toughness of cast iron matrix, solving the problem that the wear resistance and toughness of traditional single metal materials are difficult to match together. It has become one of the key breakthrough advanced materials for current research and industrialization. It is also a major development trend of cutting-edge technology in the future and a core basic component for the development of high-end equipment. Ceramic particles have good bonding strength with metal matrix, composite materials have high wear resistance, and the service life is 1.5-4 times that of existing wear-resistant composite materials. It is an advanced technology and standard in the wear-resistant materials industry.

Our company's products

Our company has been engaged in the development of composite materials and industrial research of composite castings for many years. The various types of ceramic particle reinforced wear-resistant iron-based composite castings (hammers, blow bars, grinding rollers, grinding discs, etc.) we produce have stable performance and have reached the international leading level and have achieved industrial production. Related castings of different specifications have been put into use in the wear-resistant parts market of mining, metallurgy, cement, power and other industries, and have achieved batch export of products.

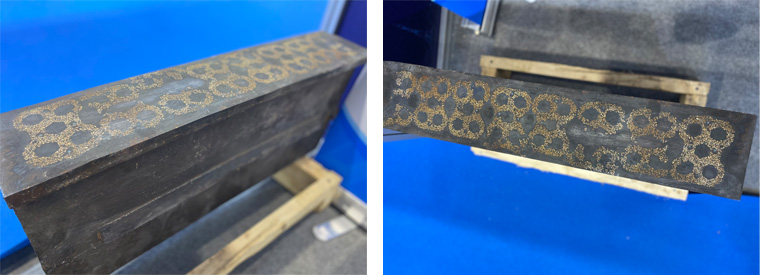

Ceramic composite blow bar produced by our company

Ceramic composite hammer head produced by our company

Ceramic compound grinding rollers and grinding discs produced by our company