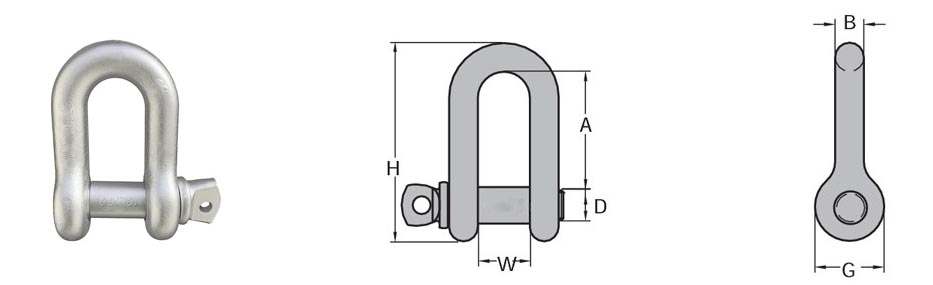

D-type shackle is a kind of sling, also known as lifting shackle and connecting shackle. The shackle models of the zhili new material production include D-type shackle and bow shackle, as well as round and C-type slings. The difference between D-type shackle and bow shackle is that the former is mainly used to connect slings, while the latter is mainly used for lifting.

Common materials for shackles include carbon steel, alloy steel, stainless steel, high-strength steel, etc. Surface treatment is generally divided into galvanizing (hot-dip and electroplating), painting, etc. D-type shackles are widely used in various industries such as electricity, metallurgy, petroleum, machinery, railways, chemicals, ports, mining, and construction.

The common specifications of rated load of shackles are 0.33T, 0.5T, 0.75T, 1T, 1.5T, 2T, 3.25T, 4.75T, 6.5T, 8.5T, 9.5T, 12T, 13.5T, 17T, 25T, 35T, 55T, 85T, 120T, 150T. (The largest shackle in the world can reach more than 1000T, among which the Swedish GUNNEBO heavy-duty shackle can reach 1200T, and the American CROSBY shackle can reach 1500T.)

The better shackles are generally made of alloy steel, which has changed the history of ordinary carbon steel in the past. The national standard shackles include general lifting shackles, marine shackles and ordinary shackles. They are heavy and large in size, and are generally installed in places where they are not often disassembled. When choosing a shackle, you should pay attention to the safety factor, which is generally 4 times, 6 times and 8 times.

The shackles we produce have the following characteristics:

●Forged and heat-treated with high-quality alloy structural steel.

●Small size, light weight, high strength, etc.

●Each shackle body has a working load and model identification

●The shackle surface can be electro-galvanized or hot-dip galvanized according to customer requirements

●The maximum test load is 2 times the rated load, and the minimum breaking load is 4 times the rated load.

●High-strength shackles with a 6-fold coefficient can be provided upon request.

●Complies with national standard technical requirements and testing methods.

●Special size customization is acceptable